Nanomaterials for Leather Production

Uswatun Hasanah, Muhammed Shah Miran, Md. Mominul Islam

Leather is used to make various daily life goods including footwear, clothing, automobile seats, furniture, etc. from prehistoric time. Various defects can occur either due to failure of controlling the factors of processing or due to low grade of raw material or both. The tanned leathers are, before use, necessarily being passed through different processes including re-tanning, filling, coating the surface with dyes, and other functional materials for protecting the surface of leather. Nanoparticles of natural and synthetic polymers, metal ions, metal oxides, metal etc. have been used for finishing tanned leather in providing them adequate quality as per the demand of buyers. In this chapter, the potential of using nanomaterials in different steps of leather processing and finishing are focused.

Keywords

Leather Processing, Nanoparticles, Nano-preservation, Nano-tannage, Nano-dying, Nanofinishing

Published online , 30 pages

Citation: Uswatun Hasanah, Muhammed Shah Miran, Md. Mominul Islam, Nanomaterials for Leather Production, Materials Research Foundations, Vol. 148, pp 170-199, 2023

DOI: https://doi.org/10.21741/9781644902554-6

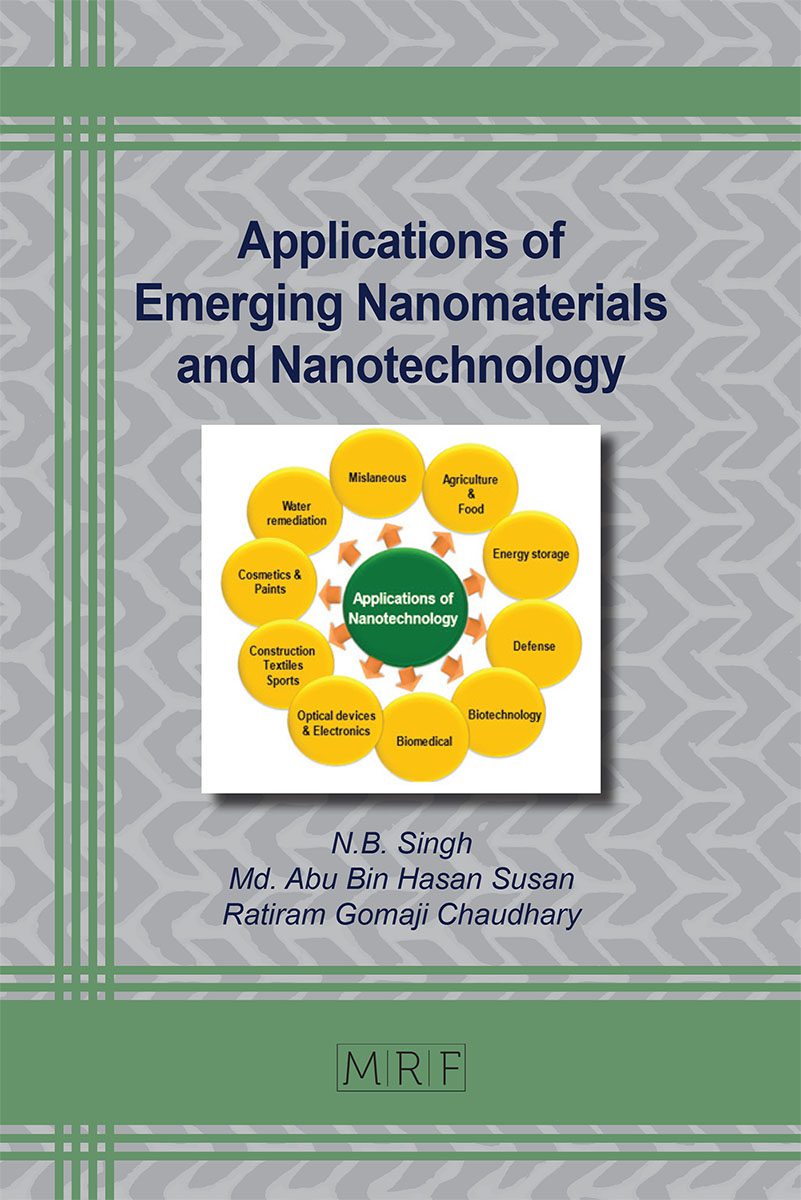

Part of the book on Applications of Emerging Nanomaterials and Nanotechnology

References

[1] T. C. Thorstensen, Practical Leather Technology, Third edition (1985).

[2] S. S. Dutta, An introduction to the principles of leather manufacture, Fourth edition (1999).

[3] A. Covington, Modern tanning chemistry, Chem Soc Rev 26(1997)111–126. https ://doi.org/10.1039/cs997 26001 11

[4] B. R. Williams, R. A. Gelman, D. C. Poppke, K. A. Piez, Collagen fibril formation, J Bio Chem 253(1978)6578–6585.

[5] M. M. Taylor, M. B. Medina, J. Lee, L. P. Bumanlag, N. P. Latona, E. M. Brown, C. K. Liu, Treatment of hides with tara-modified protein products, J Am Leather Chem Assoc 108(2013)438–444.

[6] A. Gautieri, S. Vesentini, A. Redaelli, M. J. Buehler, Hierarchical structure and nanomechanics of collagen microfibrils from the atomistic scale up. Nano Lett 11(2011)757–766. https://doi.org/10.1021/nl103943u

[7] Leather Facts, 3rd edition, New England Tanners Club, Peabody, MA, (1994)21.

[8] J. M. Buehler, Nature designs tough collagen, explaining the nanostructure of collagen fibrils, PNAS 103(33)(2006)12285–12290. https://doi.org/10.1073/pnas.0603216103

[9] L. Castaneda, J. Valle, N. Yang, S. Pluskat, K. Slowinska, Collagen cross-linking with Au nanoparticles, Biomacromol 9(2008)3383–3388. https://doi.org/10.1021/bm800793z

[10] Y. Li, B. Wang, Z. Li, L. Li, Variation of pore structure of organosilicone-modified skin collagen matrix, J Appl Polym Sci 134(2017)44831 https://doi.org/10.1002/app.44831

[11] T. Ushiki, The three-dimensional ultrastructure of the collagen fibers, reticular fibers and elastic fibers: a review, Kaibogaku Zasshi 67(1992)186–199.

[12] S. Sangeetha, U. Ramamoorthy, K. J. Sreeram, B. U. Nair, Enhancing collagen stability through nanostructures containing chromium (III) oxide, Colloids Surf B 100(2012)36–41. https ://doi.org/10.1016/j. colsu rfb.2012.05.015

[13] C. Gaidau, M. Guirginca, T. Dragomir, A. Petica, W. Chen, Study of collagen and leather functionalization by using metallic nanoparticles. J Optoelectron Adv Mater 12(10)(2010)2157–2163.

[14] R. Wahab, I. Hwang, H. S. Shin, Y. S. Kim, J. Musarrat, M. Siddiqui, In: Tiwari A, Mishra AK, Kobayashi H, Turner APF (eds) Intelligent nanomaterials: processes, properties, and applications, Scrivener Publishing LLC, Salem, (2012)183–212.

[15] C. You, C. Han, X. Wang, et al. The progress of silver nanoparticles in the antibacterial mechanism, clinical application and cytotoxicity, Mol Biol Rep 39(2012)9193–9201. https ://doi.org/10.1007/ s1103 3-012-1792-8

[16] C. F. Carter, H. Lange, S. V. Ley, I. R. Baxendale, B. Wittkamp, J. G. Goode, N. L. Gaunt, React IR Flow Cell: A new analytical tool for continuous flow chemical processing, Organic Process Research 14(2010)393–404. https://doi.org/10.1021/op900305v

[17] J. H. Sharphouse, Leather technician’s handbook. Leather Producer’s Association, (1983)104. ISBN 0-9502285-1-6.

[18] E. Heidemann, Fundamentals of leather manufacture. In: Eduard Roether KG (ed), (1993)296. ISBN 3-7929-0206-0.

[19] G. Oberdörster, A. Maynard, K. Donaldson, V. Castranova, J. Fitzpatrick, K. Ausman, D. Lai, Principles for characterizing the potential human health effects from exposure to nanomaterials: elements of a screening strategy. Part. Fibre Toxicol 2(2005)8.

[20] C. Buzea, I. I. Pacheco, K. Robbie, Nanomaterials and nanoparticles: sources and toxicity, Biointerphases 2(2007) MR17–MR71. https://doi.org/10.1116/1.2815690

[21] Z. J. Deng, M. Liang, I. Toth et al., Plasma protein binding of positively and negatively charged polymer-coated gold nanoparticles elicits different biological responses, Nanotoxicology 7(2013)314–322. http://dx.doi.org/10.3109/17435390.2012.655342

[22] M. Sajid, M. Ilyas, C. Basheer, M. Tariq, M. Daud, N. Baig, F. Shehzad, Impact of nanoparticles on human and environment: review of toxicity factors, exposures, control strategies, and future prospects, Environ Sci Pollut Res 22(2015)4122–4143. https://doi.org/10.1007/s11356-014-3994-1

[23] J. Kanagaraj, P. Sastry, C. Rose, Effective preservation of raw goat skin for the reduction of total dissolved solids, J Clean Prod 13(2005)959–996. https://doi.org/10.1016/j.jclepro.2004.05.001

[24] B. S. Gholizadeh, F. Buazar, S. M. Buazar, S. M. Mousavi, Enhanced antibacterial activity, mechanical and physical properties of alginate/ hydroxyapatite bionanocomposite film. Int J Biol Macromol 116(2018)786–792. https ://doi.org/10.1016/j.ijbio mac.2018.05.104

[25] B. G. Cousins, H. E. Allison, P. J. Doherty, C. Edwards, M. J. Garvey, D. S. Martin et al., Effects of a nanoparticulate silica substrate on cell attachment of Candida albicans, J Appl Microbiol 102(2007)757–765. https://doi.org/10.1111/j.1365-2672.2006.03124.x

[26] O. Yamamoto, T. Ohira, K. Alvarez, M. Fukuda, Antibacterial characteristics of CaCO3-MgO composites, Mater Sci Eng B 173(2010)208–212. https ://doi.org/10.1016/j.mseb.2009.12.007

[27] N. Duran, P. D. Marcato, R. D. Conti, O. L. Alves, F. T. M. Costa, M. Brocchi, Potential use of silver nanoparticles on pathogenic bacteria, their toxicity, and possible mechanisms of action, Braz Chem Soc 21(2010)949–959. https://doi.org/10.1590/S0103-50532010000600002

[28] T. Jin, Y. He, Antibacterial activities of magnesium oxide (MgO) nanoparticles against foodborne pathogens, J Nanopart Res 13(2011)6877–6885. https://doi.org/10.1007/s11051-011-0595-5

[29] M. A. Ansari, H. M. Khan, A. A. Khan, R. Pal, S. S. Cameotra, Antibacterial potential of Al2O3 nanoparticles against multidrug resistance strains of Staphylococcus aureus isolated from skin exudates, J. Nanoparticle Res 15 (2013)1970. https ://doi.org/10.1007/ s1105 1-013-1970-1

[30] A. P. Ingle, N. Duran, M. Rai, Bioactivity, mechanism of action and cytotoxicity of copper-based nanoparticles: a review, Appl Microbiol Biotechnol 98(2014) 1001–1009. https ://doi.org/10.1007/ s0025 3-013-5422-8

[31] M. Shah, V. Badwaik, Y. Kherde, H. K. Waghwani, T. Modi, Z. P. Aguilar, et al. Gold nanoparticles: various methods of synthesis and antibacterial applications, Front Biosci 19(2014)1320–1344. https://doi.org/10.2741/4284

[32] M. E. El-Zowalaty, S. H. H. Al-Ali, M. I. Husseiny, B. M. Geilich, T. J. Webster, M. Z. Hussein, The ability of streptomycin-loaded chitosan coated magnetic nanocomposites to possess antimicrobial and antituberculosis activities, Int J Nanomed 10 (2015)3269–3274. https ://doi.org/10.2147/ijn.s7446 9.

[33] H. M. Yadav, J. Kim, S. H. Pawar, Developments in photocatalytic antibacterial activity of nano TiO2: A review, Korean J Chem Eng 33(2016)1989–1998. https ://doi.org/10.1007/s1181

[34] A. B. Moghaddam, M. Moniri, S. Azizi, R. A. Rahim, A. B. Ariff, W. Z. Saad, F. Namvar, M. Navaderi, Biosynthesis of ZnO nanoparticles by a new Pichia kudriavzevii yeast strain and evaluation of their antimicrobial and antioxidant activities, Molecules 22(2017)872. https://doi.org/10.3390/molecules22060872

[35] P. Thanikaivelan, J. R. Rao, B. U. Nair, T. Ramasami, Progress and recent trends in biotechnological methods for leather processing, Trend Biotechnol 22 (2004)181–188. https ://doi.org/10.1016/j.tibtech.2004.02.008

[36] N. George, P. S. Chauhan, V. Kumar, N. Puri, N. Gupta, Approach to eco-friendly leather: characterization and application of an alkaline protease for chemical free dehairing of skins and hides at pilot scale, J Clean Prod 79 (2014)249–257. https ://doi.org/10.1016/j.jclep ro.2014.05.046

[37] G. Murugappan, M. J. Zakir, G. C. Jayakumar, Y. Khambhaty, K. J. Sreeram, J. R. Rao, A novel approach to enzymatic unhairing and fiber opening of skin using enzymes immobilized on magnetite nanoparticles, ACS Sustain Chem Eng 4 (2016)828–834. https://doi.org/10.1021/acssuschemeng.5b00869

[38] G. Murugappan, K. J. Sreeram, Effective use of enzymatic processes in beamhouse through nanoparticle immobilization, XXXV. Congress of IULTCS (2019).

[39] G. Murugappan, Y. Khambhaty, K. J. Sreeram, Protease immobilized nanoparticles: a cleaner and sustainable approach to dehairing of skin, Appl Nanosci 10 (2020)213–221. https ://doi.org/10.1007/s1320 4-019-01113 -2

[40] M. A. Eid, E. A. Al-Ashkara, Speciation of chromium ions in tannery effluents and subsequent determination of Cr(VI) by ICPAES, J Am Leather Chem Assoc 97(2007)451. https://doi.org/10.3126/jncs.v23i0.2102

[41] G. Mallikarjun, P. Saravanan, G. V. R. Reddy, Microemulsion solutions of acrylic copolymers for retanning applications on chrome tanned goat skins, J Am Leather Chem Assoc 97(2002)215. http://hdl.handle.net/123456789/9525

[42] X. C. Wang, H. R. An, M. Sun, Y. H. Luo, J. Y. Feng, An acrylic resin retanning agent with a reinforcing effect: Synthesized by high solids content microemulsion copolymerization, J Soc Leath Tech Ch 89(2005)164–168.

[43] J. Z. Ma, X. J. Chen, Y. Chu, Z. S. Yang, The preparation and application of a montmorillonite-based nanocomposite in leather making, J Soc Leath Tech Ch. 87(2003)131.

[44] Y. Bao, J. Z. Ma, The interaction between collagen and aldehyde acid copolymer/MMT nano-composite, J Soc Leath Tech Ch 94(2010)53.

[45] R. Usha, T. Ramasami, Effect of crosslinking agents (basic chromium sulphate and formaldehyde) on the thermal and thermomechanical stability of rat tail tendon collagen fiber, Thermochim Acta 356(1–2)(2000)59–66. https ://doi.org/10.1016/S0040-6031(00)00518 -9

[46] Š. Rýglová, M. Braun, T. Suchý, Collagen and its modifications—crucial aspects with concern to its processing and analysis, Macromol Mater Eng 302(6)(2017) 1600460. https ://doi.org/10.1002/mame.201600460

[47] Š. Rýglová, M. Braun, T. Suchý, Collagen and its modifications— crucial aspects with concern to its processing and analysis, Macromol Mater Eng 302 (2017)1600460.

[48] H. Pan, Z. J. Zhang, J. X. Zhang, H. X. Dang, The preparation and application of a nanocomposite tanning agent-MPNS/SMA, J Soc Leath Tech Ch 89(2005)153.

[49] Y. S. Liu, Y. Chen, J. Yao, H. J. Fan, B. Shi, B. Y Peng, An environmentally-friendly leather-making process based on silica chemistry, J Am Leather Chem Assoc 105(2010)84.

[50] H. J. Fan, L. Li, B. Shi, Q. He, B. Y. Peng, Characteristics of leather tanned with nano-SiO2, J Am Leather Chem Assoc 100(2005)22.

[51] D. G. Gao, J. Z. Ma, D. Gao, B. Lv, Study on diallyldimethyl ammonium chloride copolymer/nano SiO2 composite tannage, Leather Sci Eng 20(2010)45–48.

[52] Y. Li, D. Gao, J. Ma, B. Lu, Synthesis of vinyl polymer/ZnO nano-composite and its application in leather tanning agent, Mater Sci Forum 694(2011)103–107. https ://doi.org/10.4028/www.scien tific .net/MSF.694.103

[53] J. Ma, X. Lu, D. Gao, Y. Li, B. Lv, J. Zhang, Nanocomposite-based green tanning process of suede leather to enhance chromium uptake, J Clean Prod 72(2014)120–126. https ://doi.org/10.1016/j.jclepro.2014.03.016

[54] H. Pan, L. Guang-L., L. Rui-Qi, W. Su-Xia, W. Xiao-D., Preparation, characterization and application of dispersible and spherical Nano-SiO2@copolymer nanocomposite in leather tanning. Appl Surf Sci., 426(2017) 376–385. https ://doi.org/10.1016/j.apsus c.2017.07.106

[55] B. Lyu, R. Chang, D. Gao, J. Ma, Chromium footprint reduction: nanocomposites as efficient pretanning agents for cowhide shoe upper leather, ACS Sustain Chem Eng 6(4) (2018)5413–5423. https ://doi.org/10.1021/acssu schem eng.8b002 33

[56] L. Kaijun, R. Yu, Z. Ruixin, L. Ruifeng, L. Gongyan, P. Biyu, pH-sensitive and chromium-loaded mineralized nanoparticles as a tanning agent for cleaner leather production, ACS Sustain Chem Eng, 7(9) (2019)8660–8669. https ://doi.org/10.1021/acssu schem eng.9b004 82

[57] S. Jiabo, W. Chunhua, L. Hu, X. Yuanhang, L. Wei, Novel wet-white tanning approach based on Laponite clay nanoparticles for reduced formaldehyde release and improved physical performances, ACS Sustain Chem Eng 7(1) (2019)1195–1201. https ://doi.org/10.1021/acssu schem eng.8b048 45

[58] R. Zhu, C. Yang, K. Li, R. Yu, G. Liu, B. Peng, A smart high chrome exhaustion and chrome-less tanning system based on chromium (III)-loaded nanoparticles for cleaner leather processing, J Clean Prod 277(2020)123278. https ://doi.org/10.1016/j.jclep ro.2020.12327 8

[59] Y. Zhang, T. Snow, A. J. Smith, G. Holmes, S. Prabakar, A guide to high-efficiency chromium (III)-collagen cross-linking: synchrotron SAXS and DSC study, Int J Biol Macromol 126(2019)123–129.

[60] U. Hasanah, M. S. Miran, M. M. Rahman, M. M. Islam, Simultaneous reductions of production loss and environmental burden through the treatment of loose leather with non-toxic manganese dioxide nanoparticles, J. Cleaner Prod 318(2021) 128541. https://doi.org/10.1016/j.jclepro.2021.128541

[61] J. Kanagaraj, R. C. Panda, Modeling of dye uptake rates, related interactions, and binding energy estimation in leather matrix using protein, Ind Eng Chem Res 50(22)(2011)12400–12408.

[62] S. Ramalingam, J. R. Rao, Tailoring nanostructured dyes for auxiliary free sustainable leather dyeing application, ACS Sustain Chem Eng 5(6)(2017)5537–5549.

[63] S. Ramalingam, K. J. Sreeram, J. R. Rao, B. U. Nair, Organic nanocolorants: self-fixed, optothermal resistive, silica-supported dyes for sustainable dyeing of leather, ACS Sustain Chem Eng 4(5) (2016)2706–2714.

[64] O. A. Mohamed, A. B. Moustafa, M. A. Mehawed, N. H. El-Sayed, Styrene and butyl methacrylate copolymers and their application in leather finishing, J Appl Polym Sci 111(2009)1488–95.

[65] Q. Fan, J. Ma, Q. Xu, J. Zhang, D. Simion, G. Carmen, C. Guo. Animal-derived natural products review: focus on novel modifications and applications, Colloids Surf B 128(2015)181–90.

[66] R. Kothandam, M. Pandurangan, R. Jayavel, S. Gupta, A novel nano-finish formulation for enhancing performance properties in leather finishing applications, J Clust Sci 27(2016)1263–72.

[67] J. Ma, Q. Xu, J. Zhou, D. Gao, J. Zhang, L. Chen, Nano-scale core–shell structural casein based coating latex: synthesis, characterization and its biodegradability, Prog Org Coat 76(2013)1346–55.

[68] S. Sundara, N. Vijayalakshmia, S. Guptab, R. Rajaramc, G. Radhakrishnan, Aqueous dispersions of polyurethane-polyvinyl pyridine cationomers and their application as binder in base coat for leather finishing, Prog Org Coat 56(2006) 178–84.

[69] I. P. Fernandes, J. S. Amaral, V. Pinto, Development of chitosan-based antimicrobial leather coatings, Carbohydr Polym 98(2013)1229–35.

[70] L. Fang, Y. Honglei, M. Shulu, Antibacterial activity of chitosan-metal ion complexes in leather top-finishing, China Leather 38(2009)9–12.

[71] J. Xiang, L. Ma, H. Su, J. Xiong, K. Li, Q. Xia, G. Liu, Layer-by-layer assembly of antibacterial composite coating for leather with cross-link enhanced durability against laundry and abrasion, Appl Surf Sci 458(2018)978–87.

[72] H. Shi, Y. Chen, H. Fan, J. Xiang, B. Shi, Thermosensitive polyurethane film and finished leather with controllable water vapor permeability, J Appl Polym Sci 117(2010)1820–7.

[73] O. A. Mohamed, F. A. Abdel-Mohdy, Preparation of flame-retardant leather pretreated with pyrovatex CP, J Appl Polym Sci 99(2006)2039–43.

[74] H. Fan, L. Gao, Q. Wang, Research on the application of nanometer TiO2 in the leather industry, Leather Chem 28(2011)22–5.

[75] T. Wang, Y. Bao, Advances on functional polyacrylate/inorganic nanocomposite latex for leather finishing, Mater Rev 31(2017)64–71.

[76] P. Velmurugan, M. Cho, S. M. Lee, J. H. Park, S. Bae, B. T. Oh, Antimicrobial fabrication of cotton fabric and leather using green-synthesized nanosilver, Carbohydr Polym 106(2014)319–25.

[77] C. Gaidau, A. Petica, M. Ignat, O. Iordache, L. Ditu, M. Ionescu, Enhanced photocatalysts based on ag-TiO2 and ag-N-TiO2 nanoparticles for multifunctional leather surface coating, Open Chem 14(2016)383–92.

[78] J. Liu, J. Ma, Y. Bao, J. Wang, H. Tang, L. Zhang, Polyacrylate/surface-modified ZnO nanocomposite as film-forming agent for leather finishing, Int J Polym Mater Polym Biomater 63(2014)809–14.

[79] Y. Bao, C. Feng, C. Wang, J. Ma, C. Tian, Hygienic, antibacterial, UV-shielding performance of polyacrylate/ZnO composite coatings on a leather matrix, Colloids Surf A Physicochem Eng Asp 518(2017)232–40.

[80] J. Liu, J. Ma, Y. Bao, J. Wang, Z. Zhu, H. Tang, L. Zhan, Nanoparticle morphology and film-forming behavior of polyacrylate/ZnO nanocomposite, Compos Sci Technol 98(2014)64–71.

[81] W. Chen, L. Feng, B. Qu, In situ synthesis of poly (methyl methacrylate)/MgAl layered double hydroxide nanocomposite with high transparency and enhanced thermal properties, Solid State Commun 130(2004)259–63.

[82] Y. Wang, J. Ma, Q. Xu, J. Zhang, Fabrication of antibacterial casein-based ZnO nanocomposite for flexible coatings, Mater Des 113(2017)240–5.

[83] R. Kothandam, M. Pandurangan, R. Jayavel, S. Gupta, A novel nano-finish formulation for enhancing performance properties in leather finishing applications, J Clust Sci 27(2016)1263–72.

[84] H. Jing, J. Ma, W. Deng, Properties of acrylic resin/nano-SiO2 leather finishing agent prepared via emulsifier-free emulsion polymerization, Mater Lett 62(2008)2931–4.

[85] W. Zhang, J. Ma, D. Gao, Y. Zhou, C. Li, J. Zha, J. Zhang, Preparation of aminofunctionalized graphene oxide by Hoffman rearrangement and its performances on polyacrylate coating latex, Prog Org Coat 94(2016)9–17.

[86] J. Ma, X. Zhang, Y. Bao, J. Liu, A facile spraying method for fabricating superhydrophobic leather coating, Colloids Surf A Physicochem Eng Asp 472(2015)21–5.

[87] A. Petica, C. Gaidau, M. Ignat, C. Sendrea, L. Anicai, Doped TiO2 nanophotocatalysts for leather surface finishing with self-cleaning properties, J Coat Technol Res 12(2015)1153–63.

[88] C. Gaidau, A. Petica, M. Ignat, L. M. Popescu, R. M. Piticescu, I. A. Tudor, Preparation of silica doped titania nanoparticles with thermal stability and photocatalytic properties and their application for leather surface functionalization, Arab J Chem 10(2017)985–1000.

[89] Q. Xu, Q. Fan, J. Ma, Z. Yan, Facile synthesis of casein-based TiO2 nanocomposite for self-cleaning and high covering coatings: insights from TiO2 dosage, Prog Org Coat 99(2016)223–9.

[90] Y. Bao, Y. Yang, J. Ma, Fabrication of monodisperse hollow silica spheres and effect on water vapor permeability of polyacrylate membrane. J Colloid Interface Sci 407(2013)155–63.

[91] Y. Bao, Y. Yang, C. Shi, J. Ma, Fabrication of hollow silica spheres and their application in polyacrylate film forming agent, J Mater Sci 49(2014)8215–25.

[92] Q. Fan, J. Ma, Q. Xu, J. Wang, Y. Ma, Facile synthesis of chitosan-coated silica nanocapsules via interfacial condensation approach for sustained release of vanillin, Ind Eng Chem Res 57(2018)6171–9.

[93] Q. Fan, J. Ma, Q. Xu, Facile synthesis of chitosan-based silica nanocapsules for fragrance-controlled release leather finishes, XXXIII IULTCS congress proceedings, (2017) India.

[94] F. Zhang, J. Ma, Q. Xu, J. Zhou, D. Simion, G. Carmen, A facile method for fabricating room-temperature-film-formable casein-based hollow nanospheres, Colloids Surf A Physicochem Eng Asp 484(2015)329–35.

[95] Q. Fan, J. Ma, Q. Xu, W. An, R. Qiu, Multifunctional coatings crafted via layer-by- layer spraying method, Prog Org Coat 125(2018)215–21.

[96] O. Mohamed, H. Elsayed, R. Attia, A. Haroun, N. El-Sayed, Preparation of acrylic silicon dioxide nanoparticles as a binder for leather finishing, Adv Poly Technol 37(8)( 2018)3276–3286.

[97] H. Elsayed, R. Attia, O. Mohamed, A. Haroun, N. El-Sayed, Preparation of polyurethane silicon oxide nanomaterials as a binder in leather finishing, Fibers Polym 19(2018)832–842.

[98] M. K. Kaygusuz, M. Meyer, A. Aslan, The effect of TiO2-SiO2 nanocomposite on the performance characteristics of leather, Mat Res 20(4) (2017)1103–1110.

[99] K. R. Kumar, R. Jayavel, G. Sanjeev, Zinc oxide (ZnO) nanoparticles for enhancement of fastness properties in cationic finishing, J Am Leather Chem Assoc 112 (5) (2017)162–167.

[100] K. Ramkumar, P. Muthuraman, R. Jayavel, G. Sanjeev, Some novel nano-finish formulations for enhancing performance properties in leather finishing applications, J Cluster Sci 27(4)(2016)1263–1272.

[101] L. Muthukrishnan, M. Chellappa, A. Nanda, Bio-engineering and cellular imaging of silver nanoparticles as weaponry against multidrug resistant human pathogens, J Photochem Photobiol B Biol 194(2019)119–127. https ://doi.org/10.1016/j.jphot obiol .2019.03.021

[102] J. Kanagaraj, P. Sastry, C. Rose, Effective preservation of raw goat skin for the reduction of total dissolved solids, J Clean Prod 13(2005)959–964.

[103] L. Kaijun, R. Yu, Z. Ruixin, L. Ruifeng, L. Gongyan, P. Biyu, pH-sensitive and chromium-loaded mineralized nanoparticles as a tanning agent for cleaner leather production, ACS Sustain Chem Eng 7(9)(2019)8660–8669. https ://doi.org/10.1021/acssu schem eng.9b004 82

[104] D. Gurera, B. Bhushan, Fabrication of bioinspired superliquiphobic synthetic leather with self-cleaning and low adhesion, Colloids Surf A Physicochem Eng Asp 545(2018)130–137. https ://doi.org/10.1016/j.colsu rfa.2018.02.052.

[105] J. Singh, T. Dutta, K. H. Kim et al., Green synthesis of metals and their oxide nanoparticles: applications for environmental remediation, J Nanobiotechnol 16 (2018)84. https ://doi.org/10.1186/s12951-018-0408-4